1013

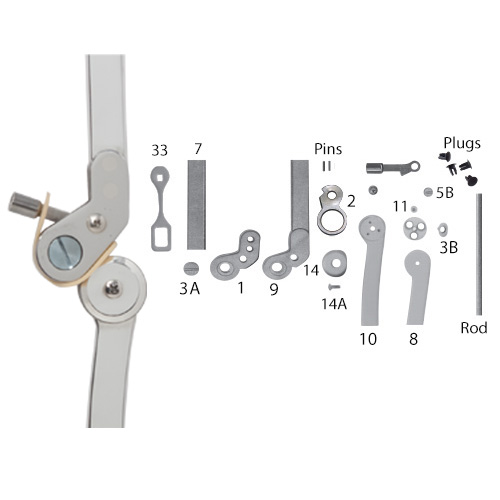

Posterior Offset Adjustable Knee Joint

Model 1013 is a posterior offset adjustable knee joint that allows the orthotist to fine tune the A-P alignment of the knee. The A-P alignment and the extension/flexion angle can be changed by simply removing two screws; this allows easy adjustability in 6° increments without the need to physically alter the angle of the uprights. The 1013 comes equipped with optional bail locks and urethane straps, which can be used to provide automatic locking when the knee joints reach full extension.

HCPCs

The responsibility of accurate coding lies with the patient care facility that is billing for the product and service. The HCPCS Alpha-Numeric System is subject to revisions and periodic updates and should be consulted prior to billing.

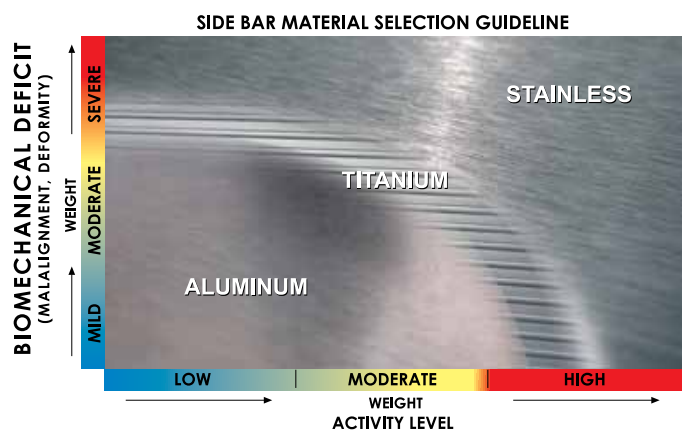

Knee Joint Selection Guide

Discretion in choosing a joint size and designing an appropriate orthosis should be used by the orthotist in all cases. We would reference and support the approach described by Lunsford and agree that successful orthotic management requires a clear understanding of the condition being treated and a realistic plan to address the biomechanical deficits presented.

For optimal orthotic management, the mechicanical demands to be placed upon the orthosis for any given treatment must be understood prior to material selection.

The selection of the correct materials is often the difference between success and failure and we believe that the orthotist is trained and the best qualified to match the characteristics of the material to the biomechanical and functional needs of the patient.

Discretion in choosing a joint size, selecting the Side Bar Material, and designing an appropriate orthosis should be used by the orthotist in all cases. The following factors are commonly used by orthotists to help determine the level of Biomechanical Deficit. Practical issues including compliance, occupation, environment and social factors should also be taken into consideration.

Biomechanical Deficit Factors

- Single or multiple plane involvement

- Single or multiple segment involvement

- Muscle strength/weakness

- Range-of-motion

- Skeletal and/or joint alignment — malalignment

- Mobile or fixed deformity

- Presence and magnitude of joint contracture

- Presence/extent of spasticity

- Proprioceptive and cognitive skills

- Progressive or non progressive condition

| Biomechanical Deficit | Mild | Moderate | Severe | |||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Activity Level | Low | Moderate | High | Low | Moderate | High | Low | Moderate | High | |||||||||||||||||||

|

Patients Weight LBS (kg) |

80-140 (36-64) |

140-210 (64-95) |

210-320 (95-145) |

80-140 (36-64) |

140-210 (64-95) |

210-320 (95-145) |

80-140 (36-64) |

140-210 (64-95) |

210-320 (95-145) |

80-140 (36-64) |

140-210 (64-95) |

210-320 (95-145) |

80-140 (36-64) |

140-210 (64-95) |

210-320 (95-145) |

80-140 (36-64) |

140-210 (64-95) |

210-320 (95-145) |

80-140 (36-64) |

140-210 (64-95) |

210-320 (95-145) |

80-140 (36-64) |

140-210 (64-95) |

210-320 (95-145) |

80-140 (36-64) |

140-210 (64-95) |

210-320 (95-145) |

|

| 1001 | B | A | — | B | A | — | B/A | A | — | B | A | — | B | A | — | B/A | A | — | B/A | A | A | B/A | A | — | B/A | A | — | |

| 1002 | B | A | — | B | A | — | B/A | A | — | B | A | — | B | A | — | B/A | A | — | B/A | A | A** | B/A | A | A** | B/A | A** | — | |

| 1003 | B | A | — | B | A | — | B/A | A | — | B | A | — | B | A | — | B/A | A | — | B/A | A | — | A | — | — | A | — | — | |

| 1004 | B | A | — | B | A | — | B/A | A | — | B | A | — | B | A | — | B/A | A | — | B/A | A | — | A | A | — | A | — | — | |

| 1006* | B | A | — | B | A | — | B/A | A | — | B | A | — | B | A | — | B/A | A | — | B/A | A | — | A | A | — | — | — | — | |

| 1007* | B | A | — | B | A | — | B/A | A | — | B | A | — | B | A | — | B/A | A | — | B/A | A | — | A | — | — | — | — | — | |

| 1010* | B | A | — | B | A | — | B/A | A | — | B | A | — | B | A | — | B/A | A | — | B/A | A | — | A | — | — | — | — | — | |

| 1012 | B | A | — | B | A | — | B/A | A | — | B | A | — | B | A | — | B/A | A | — | B/A | A | — | B/A | A | — | — | — | — | |

| 1013* | — | A | — | — | A | — | A | A | — | — | A | — | — | A | — | A | A | — | A | A | — | A | — | — | — | — | — | |

| 1015 | B | A | — | B | A | — | B/A | A | — | B | A | — | B | A | — | B/A | A | — | B/A | A | A | A | A | — | — | — | — | |

| 1017 | B | A | — | B | A | — | B/A | A | — | B | A | — | B | A | — | B/A | A | — | B/A | A | — | B/A | A | — | A | A | — | |

| 1017-A38* | — | — | A | — | — | A | — | — | A | — | — | A | — | — | A | — | — | A | A | A | A | A | A | A | A | A | A | |

| 2004* | B | B | — | B | B | — | — | — | — | B | B | — | B | B | — | — | — | — | B | — | — | — | — | — | — | — | — | |

| 2009* | B | A | — | B | A | — | B/A | A | — | B | A | — | B | A | — | B/A | A | — | B/A | A | — | A | A | — | A | — | — | |

| S2001* | B | A | — | B | A | — | B/A | A | — | B | A | — | B | A | — | B/A | A | — | B/A | A | — | A | A | — | A | — | — | |

| S2003* | B | A | — | B | A | — | B/A | A | — | B | A | — | B | A | — | B/A | A | — | B/A | A | — | A | A | — | A | — | — | |

- * Not available with titanium uprights.

- ** Consider ordering with Heavy Duty Rings, Model 1002-A#4HD.

- NOTE: Model 1017-A38 is available with aluminum uprights only.

Steel and Aluminum Alloys

Steel is stronger and stiffer than aluminum allow; aluminum allow has a lower density making it lighter. Steel is fatigure resistant and combines high rigidity, or ductility depending on the alloy. The main disadvantage of steel is its weight. The major benefit of aluminum in orthotics is its high strength to weight ratio. Aluminum does however have a lower endurance limit under repreated dynamic loading conditions than does steel. A common clinical question relates to the upright of a lower extremity orthosis in which deformation under bending stresses is very important. In general terms, if loading conditions are known to be great or highly repetitive, steel is superior to aluminum.

Considerations for preventing failure:

- Fatigue

- Stress Concentration

- Finishing

- Bend Radii

- Design

Downloadable Version

Downloadable Version